- Décarbonation des utilités

A biomass boiler plant and low-carbon steam for LIS by Lesaffre

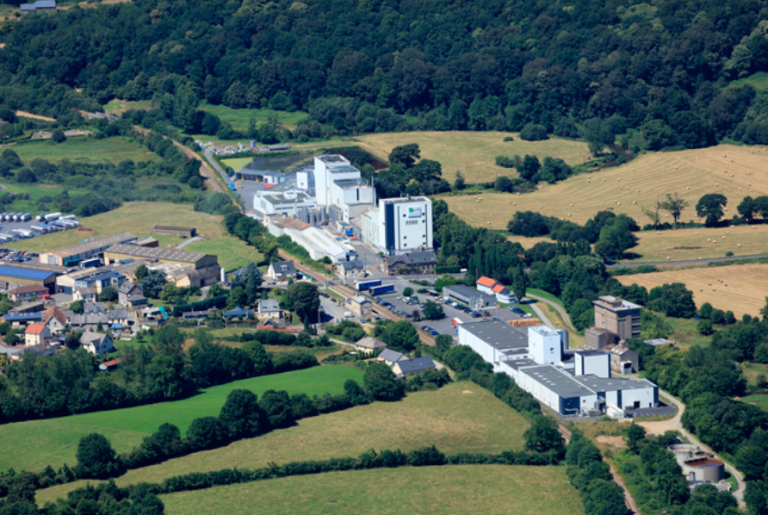

The industrial site of LIS by Lesaffre in Cérences (Normandy) specialises in custom drying for a variety of projects, including aromatic powders, natural colourants, protein hydrolysates, plant extracts, enzymes, fibers and sweet products for coating. This industrial biotechnology division is part of the Lesaffre Group, a global player in yeast production, the fermentation of microorganisms, and animal feed.

A low-carbon steam supply for a key player in industrial biotechnology

As part of a commitment to reducing its carbon footprint and controlling its energy consumption, LIS asked Idex to decarbonise its production of industrial steam. In this way, LIS has been able to reduce its dependence on fossil fuels by using biomass for the drying process. Today, low-carbon technologies are implemented in 85% of its customer services.

Reducing carbon emissions and creating jobs

Through the solution developed by Idex, the LIS plant has cut carbon emissions from industrial production by 13,500 tonnes per year, and improved the management of steam production. Idex is operating the new industrial steam boiler plant as part of a 15-year contract guaranteeing plant availability of 100%. To achieve this, the boiler plant is equipped with two gas-fired boilers to complement the biomass boiler, bringing total boiler plant capacity to 37 tonnes/hour and over 110,000 tonnes of steam per year.

The new industrial boiler plant has also created a number of direct and indirect jobs in biomass supply and mechanical maintenance. To meet energy needs, Idex has developed a sustainable, local supply chain for wood chips, supplemented by 30% end-of-life packaging wood, shipped by around five semi-trailers of 90 m3 every day.

“LIS France made the ambitious decision to decarbonise its drying activities, and we are delighted to see this major renewable energy project become a reality. We believe that reducing our exposure to fossil fuels and slashing the accompanying carbon emissions is vital to the long-term future of our drying business. We are particularly excited to be starting this long-term partnership with Idex, and to have access to their know-how and expertise.”

110,000 tonnes of steam produced / year

85% renewable energy

13,500 tonnes of CO2 emissions avoided / year

34% subsidy from the ADEME as part of the France Relance programme