- Exploitation & Pilotage intelligent des installations

Idex installs a cogeneration plant for manufacturer BASF

In northern France, BASF manufactures, develops and markets paints and varnishes, primarily for the automotive sector at its site in Breuil-le-Sec.

The company views energy efficiency as a key priority, not only for reasons relating to climate protection and resource conservation, but also for its economic benefits.

Optimised installations

To optimise the energy performance of BASF, , Idex deployed a dedicated multi-technical team to operate two boiler rooms.

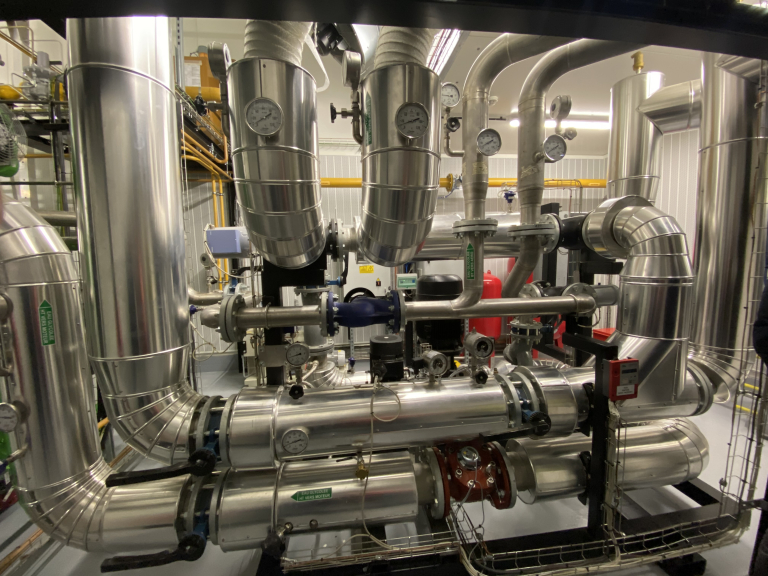

Idex installed a cogeneration engine for our customer.

The idea: to recover the waste heat produced by an electrical generator.

Using natural gas or other fuels, these 2-in-1 installations produce electricity, which is sold back to the grid, and heat, which is used to supply the building’s thermal installations or even a heating network, depending on the cogeneration capacity.

Producing electricity and heat at the same time with the same primary energy source and the same installation not only saves energy, for savings on the final bill, but also significantly reduces our customer's CO2 emissions.